In the world of textiles, few materials hold as much historical and cultural significance as linen and cotton. These natural fibers have been used for centuries in the creation of various fabrics, each with its unique characteristics and qualities. In this article, we will delve into the world of the finest linen used, unmasking its powerhouse status and comparing it to the clout of cotton.

What Is Linen Fabric?

The flax plant (Linum usitatissimum) provides the fibers used to create linen cloth, a type of textile. For its adaptability, flax has been grown for thousands of years, and linen is one of the oldest textiles still in use today. Starting with the harvesting of flax plants, numerous processes are involved in producing flax fiber for linen.

Linen yarn is known for its strength and durability. It is typically spun using a technique called wet spinning, where the fibers are dampened to increase their flexibility during the spinning process. The resulting linen yarn can be woven or knitted into various fabrics, ranging from lightweight to heavyweight depending on the desired application.

Linen fabric is highly regarded for its unique properties. It is known for its exceptional breathability, allowing air to flow through the fabric and providing comfort in warm or hot weather. Linen also has excellent moisture-wicking capabilities, absorbing moisture while still feeling dry to the touch. It is a highly durable fabric, often becoming softer and more lustrous with each wash. Linen is also hypoallergenic, making it a suitable choice for individuals with sensitive skin.

In terms of appearance, linen fabric has a natural luster and slightly textured surface, which adds to its aesthetic appeal. It is available in various weights and weaves, allowing for versatile applications in clothing, home textiles, and even industrial sectors.

History of Linen

One of the oldest fabrics in the world, linen fabric has a history that goes back thousands of years. Ancient civilizations that raised flax, the plant from which linen fibers are derived, are where linen first appeared.

The cultivation of flax and the production of linen can be traced to ancient Egypt, where linen was highly valued and played a significant role in society and culture. The Egyptians considered linen to be a symbol of purity, and it was commonly used for clothing, bedding, and burial shrouds. Linen was also used for sails, ropes, and other practical applications due to its strength and durability.

Linen production techniques spread throughout the ancient world, reaching ancient Mesopotamia, Greece, and Rome. The Romans, in particular, embraced linen fabric and used it extensively for clothing and household items. Linen garments were associated with wealth and social status, and the Romans even used linen as currency in some instances.

During the Middle Ages, linen production spread further across Europe, with regions like Belgium, France, and the Netherlands becoming renowned for their high-quality linen products. Linen fabric remained a staple in clothing and household textiles, particularly among the upper classes.

In the 17th and 18th centuries, linen production saw significant advancements, especially in Ireland. The Irish linen industry became highly successful, producing fine linens that were sought after worldwide. Linen production also expanded in other parts of Europe, such as Scotland, England, and Northern Germany.

With the Industrial Revolution in the 19th century, linen production underwent significant changes. Mechanized spinning and weaving processes were introduced, increasing efficiency and output. However, the popularity of cotton began to rise during this period, and linen faced competition from this new textile.

In the 20th century, linen production experienced fluctuations due to changing fashion trends and the introduction of synthetic fibers. However, linen has maintained its reputation as a premium fabric, prized for its natural properties and luxurious feel.

In recent years, there has been a resurgence of interest in linen due to its sustainable and eco-friendly qualities. Flax plants require less water and fewer pesticides compared to other crops, making linen production more environmentally friendly. As consumers have become more conscious of sustainability, linen has gained renewed popularity in various industries, including fashion, home textiles, and interior design.

Today, linen fabric continues to be valued for its breathability, durability, hypoallergenic properties, and natural aesthetic. It is used in a wide range of applications, from clothing and bedding to upholstery and industrial uses. The rich history and enduring appeal of linen make it a fabric with a timeless legacy.

What Is Linen Used For

Because of its special characteristics, linen is used in many different sectors. It is frequently used in clothes, especially for summer garments like shirts, skirts, and pants. Because of its toughness and tolerance to high temperatures, linen is also a good material for upholstery, drapes, and kitchen and table linens. Additionally, linen is utilized in the manufacture of canvas, paper, and even in the automobile and aerospace industries.

How Is Linen Fabric Made?

1. Harvesting

The first step in linen production is the harvesting of flax plants. Flax is typically grown in cooler climates and is ready for harvest when the lower part of the plant turns yellow and the seeds begin to turn brown.

2. Retting

After harvesting, the flax stems undergo a process called retting. Retting involves exposing the stems to moisture, either by soaking them in water or spreading them in fields and allowing them to be exposed to dew, rain, or a combination of both. This process helps to break down the pectin that holds the fibers together.

3. Drying

Once the retting process is complete, the flax stems are dried to remove excess moisture. They are typically spread out in fields or on racks to dry in the sun.

4. Threshing

After drying, the flax stems are mechanically or manually beaten to remove the outer bark or straw, revealing the long, fine flax fibers within. This process is known as threshing, and it separates the fibers from the woody stem.

5. Scutching

The next step is scutching, where the fibers are further separated from the woody matter. Scutching involves beating the flax stalks with wooden blades or rollers to remove the remaining straw and impurities, leaving behind the long flax fibers.

6. Hackling

Following scutching, the flax fibers are combed through a process called hackling. Hackling involves running the fibers through a series of metal combs with fine, sharp teeth. This process helps to align the fibers, remove any remaining impurities, and create long, parallel strands of natural fiber from flax called line flax.

7. Spinning

The line flax is then spun into yarn or thread. Linen yarn can be spun using different methods, including hand spinning or mechanical spinning. Wet spinning is a common technique used for linen, where the fibers are dampened to increase their flexibility during the spinning process. The resulting linen yarn is then ready to be woven or knitted into fabric.

8. Weaving

Linen yarn is woven on looms to create linen fabric. Different weaving patterns and techniques can be used to create various types of linen fabric, ranging from lightweight and sheer to heavyweight and textured.

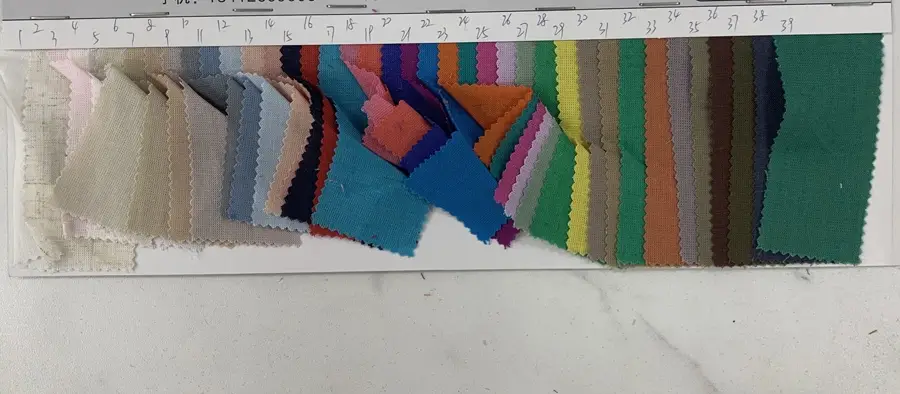

After weaving, the linen fabric is often finished through processes such as bleaching, dyeing, or applying special finishes to enhance its appearance or performance properties.

How Is Linen Fabric Used?

Linen fabric is used in a wide range of applications due to its unique properties and versatile nature. Here are some common uses of linen fabric:

- Apparel: Linen is commonly used in the production of clothing, particularly for warm weather and summer wear. It is favored for its breathability and moisture-wicking capabilities, which help keep the body cool and dry. Linen clothing includes shirts, blouses, dresses, skirts, trousers, shorts, and suits. Its natural luster and slightly textured appearance add to its aesthetic appeal.

- Home Textiles: Linen is widely used in home textiles, bringing a touch of elegance and sophistication to interiors. It is commonly used for bed sheets, pillowcases, duvet covers, and bedspreads. Linen towels are highly absorbent and quick-drying, making them ideal for bath towels, hand towels, and kitchen towels. Linen is also used for tablecloths, napkins, placemats, and curtains, adding a stylish and natural look to the dining area.

- Upholstery: Linen fabric is a popular choice for upholstery due to its durability and resistance to high temperatures. It is used for covering furniture such as chairs, sofas, ottomans, and headboards. Linen upholstery adds a touch of elegance and a relaxed, casual vibe to interior spaces.

- Draperies: Linen’s natural drape and soft texture make it suitable for curtains, drapes, and window treatments. Linen draperies can enhance the aesthetics of a room, providing a light and airy feel while offering privacy and light control

Where Is Linen Fabric Produced?

Linen fabric is produced from flax fibers, and historically, the production of linen has been associated with several countries. However, the primary regions known for linen production are:

Europe: Linen has a long history of production in Europe, particularly in countries such as Belgium, Ireland, France, Lithuania, and the Netherlands. These countries have a favorable climate for growing flax, which is the plant used to produce linen fibers.

China: China is one of the largest producers of linen fabric. It has a significant flax cultivation industry and a well-established linen manufacturing sector.

Russia: Russia has a long tradition of linen production, particularly in regions like the Baltic states, which include Latvia, Lithuania, and Estonia.

Belarus and Ukraine: These countries also have a strong linen industry and are known for producing high-quality linen fabric.

India: India has a rich history of linen production and is known for its handloom linen textiles.

It’s worth noting that linen production can occur in other parts of the world as well, but these regions have traditionally been associated with the largest and most established linen industries.

How Much Does Linen Fabric Cost?

The cost of linen fabric can vary depending on several factors, including the quality of the fabric, the weave, the brand, and the supplier. Generally, linen fabric is considered a higher-end textile, and its cost tends to be higher compared to fabrics like cotton or polyester. Some factors that can influence the cost of linen fabric are quality, weave and weight, organic or sustainable production, brand and reputation, and the market demand and availability.

It is important to note that linen fabric’s higher cost is often justified by its unique properties, including breathability, durability, and luxurious feel. Linen is also considered a premium and sustainable material, which can contribute to its higher price compared to other fabrics.

When purchasing linen fabric, it is recommended to compare prices from different suppliers, consider the fabric’s quality, and determine if any additional factors, such as organic production or brand reputation, affect the cost.

What Different Types of Linen Fabric Are There?

1. Damask linen

Damask linen refers to a specific type of linen fabric that is characterized by its intricate woven patterns and designs. Damask is typically made using a combination of satin weave and twill weave techniques, resulting in a reversible fabric with a subtle sheen.

Damask linen is known for its elegance and is often used for high-end home textiles and formal table linens. It has a luxurious feel and a refined appearance that adds a touch of sophistication to any setting. Damask linen tablecloths, napkins, and runners are commonly used for special occasions, formal dinners, and events.

2. Plain-woven linen

Plain-woven linen refers to a type of linen fabric that is woven using a simple plain weave structure. The plain weave is the most basic and common weaving pattern, characterized by an alternating over-under interlacing of warp and weft threads.

Due to its simplicity and understated appearance, plain-woven linen is often used for everyday clothing such as shirts, blouses, dresses, skirts, and trousers. Its breathability and moisture-wicking properties make it a popular choice for warm-weather garments. Plain-woven linen is also used for household textiles like tablecloths, napkins, dish towels, and curtains.

3. Loosely-woven linen

Loosely-woven linen refers to a type of linen fabric that is woven with a more open and relaxed structure, resulting in a fabric that has a more airy and lightweight feel. Unlike tightly-woven linen fabrics, which have closely spaced warp and slightly longer weft threads, loosely-woven linen features more space between the threads, creating a more open weave.

Due to its lightweight and breathable nature, loosely-woven linen is often used for garments such as summer dresses, blouses, shirts, and lightweight trousers. It is also popular for creating breezy and flowy home textiles like curtains, lightweight throws, and sheer draperies.

4. Sheeting linen

Sheeting linen refers to a type of linen fabric that is specifically designed and woven for bed sheets. It is a durable and smooth fabric that offers comfort and breathability for a restful sleep experience.

Sheeting linen is typically woven with a plain weave structure, featuring an equal number of warp and weft threads. This results in a balanced and regular grid-like pattern on the fabric’s surface. The plain weave construction allows for a smooth and soft texture, making it ideal for bedding applications.

Differences Between Linen and Cotton: Linen vs. Cotton

1. Sorce

Linen is derived from the flax plant (Linum usitatissimum), while cotton comes from the cotton plant (Gossypium).

2. Fiber Characteristics

Linen fibers are longer and stronger compared to cotton fibers. Linen fibers have a natural luster and are slightly thicker, while cotton fibers are shorter and finer.

3. Durability

Linen is known for its exceptional strength and durability, often improving with use and age. Cotton is also durable but may not be as robust as linen.

4. Texture

Linen has a distinctive texture with a slightly rough and textured surface. Over time, linen becomes softer and more comfortable with each wash. Cotton has a smoother texture and is generally softer to the touch.

5. Appearance

Linen has a natural luster or sheen that gives it a subtle glow, even in its matte form. This luster adds an element of elegance and sophistication to linen fabric. In contrast, cotton has a more matte appearance and lacks the same inherent shine as linen.

6. Hypoallergenic Property

Both linen and cotton are known for its hypoallergenic properties. It has natural antibacterial and antifungal properties that resist the growth of allergens, bacteria, and mold. This can be beneficial for individuals with allergies or sensitive skin.

7. Absorbency

Linen has excellent moisture-wicking properties, absorbing moisture and quickly releasing it to the air, keeping you dry. Cotton is also absorbent but may retain moisture for longer periods.

8. Breathability

Linen is highly breathable and allows for better airflow, making it a great choice for hot and humid climates. Cotton is also breathable but may not provide the same level of cooling as linen.

9. Environmental Impact

Linen is considered more environmentally friendly as flax requires less water and fewer pesticides compared to cotton farming. Additionally, flax is a renewable resource. Cotton farming, on the other hand, requires more water and extensive use of pesticides.

10. Price

Linen is typically more expensive than cotton due to the more involved manufacturing process and the limited availability of flax compared to cotton.

Linen Care

Caring for linen properly can help maintain its quality, prolong its lifespan, and keep it looking its best. Here are some tips for caring for linen:

- Washing:

- Check the care label: Always read and follow the manufacturer’s care instructions on the garment or linen item.

- Separate colors: Sort your linen items by color to prevent color bleeding or transfer.

- Gentle cycle: Use a gentle or delicate cycle on your washing machine to minimize agitation and prevent excessive wrinkling.

- Mild detergent: Use a mild, pH-neutral detergent specifically formulated for delicate fabrics.

- Water temperature: Wash linen in cool to lukewarm water to prevent shrinkage or damage.

- Avoid bleach: Do not use chlorine bleach or harsh stain removers because they can make the fibers weak and can cause discoloration.

- Pre-treat stains: If you encounter stains, pre-treat them with a gentle stain remover or by dabbing with a mixture of water and mild detergent before washing.

- Drying:

- Air drying: It is best to air dry linen whenever possible. Hang or lay the linen item flat to dry, preferably in a shaded area to prevent direct sunlight from fading the fabric.

- Avoid wringing: Do not wring or twist linen vigorously, as it can cause creasing or distortion in the fabric.

- Reshape if needed: While the linen is damp, gently reshape the item to its original form to maintain its shape and structure.

- Ironing:

- Iron while slightly damp: Linen is easier to iron when slightly damp. If the linen has dried completely, you can mist it with water before ironing.

- Use medium heat: Set your iron to a medium heat setting, as high heat can scorch or damage linen fibers.

- Iron on the reverse side: Iron linen on the reverse side or place a pressing cloth between the iron and the fabric to prevent shine or heat marks.

- Storage:

- Clean before storage: Make sure your linen items are clean and completely dry before storing them to prevent mildew or musty odors.

- Avoid plastic bags: Store linen in breathable fabric storage bags or pillowcases to allow air circulation and prevent moisture buildup.

- Avoid hanging for long periods: Linen can stretch if hung for extended periods, so it is best to fold and stack linen items in a cool, dry place.

It’s worth noting that some individuals appreciate the natural, relaxed look of linen, including its characteristic wrinkles. If you prefer to embrace the linen wrinkles yourself, you can skip the ironing step and allow the fabric to retain its natural texture and appearance.

By following these care tips, you can help maintain the quality and beauty of your linen items and enjoy them for a long time.

How Does Linen Fabric Impact the Environment?

Linen fabric is generally considered to have a lower environmental impact compared to many other textiles. Here are several reasons why linen is considered an environmentally friendly choice:

- Sustainable Crop: Flax, the plant from which linen is made, is a sustainable crop. It requires fewer pesticides and fertilizers compared to other crops like cotton. Flax plants also have deep roots that help prevent soil erosion and improve soil quality.

- Water Efficiency: Flax plants require less water than other crops commonly used for textile production, such as cotton. This makes linen a more water-efficient choice, particularly in areas where water resources are limited or water scarcity is a concern.

- Minimal Chemical Use: The production of linen fabric typically involves fewer chemicals compared to synthetic fibers. Flax plants naturally have a resistance to pests and diseases, reducing the need for extensive chemical treatments during cultivation. Additionally, linen fibers are often processed using mechanical rather than chemical methods.

- Biodegradable and Recyclable: Linen fabric is biodegradable, meaning it can break down naturally over time, returning to the environment. This reduces its contribution to landfill waste compared to synthetic fabrics, which can persist for extended periods. Linen fabric can also be recycled and repurposed into new products.

- Durability and Longevity: Linen fabric is known for its durability and longevity. Linen garments and textiles tend to have a longer lifespan compared to many other fabrics. When cared for properly, linen items can be used for years, reducing the need for frequent replacement and lowering overall resource consumption.

- Energy Efficiency: Compared to the manufacture of synthetic fibers, linen cloth usually uses less energy. Linen fibers can be spun into yarn using mechanical spinning methods, which consume less energy compared to the chemical processes involved in the production of synthetic fibers.

- Reduced Microplastic Pollution: Unlike synthetic fibers like polyester or nylon, linen does not shed microplastic particles when washed. Microplastic pollution is a growing concern in our oceans and waterways, as these particles can harm marine life and ecosystems. Opting for natural fibers like linen helps minimize this environmental impact.

While linen fabric has several environmentally friendly qualities, it is essential to consider other aspects of its production, such as the dyeing and finishing processes. These processes can involve chemicals that may have environmental implications. Choosing organic or naturally dyed linen fabrics can help minimize the environmental impact further.

Linen fabric’s lower water consumption, minimal chemical use, biodegradability, and durability contribute to its reputation as an environmentally friendly textile choice. By choosing linen, consumers can make a positive impact on the environment and promote more sustainable practices in the textile industry.