Garment quality is an essential element in the fashion business since customer demand varies depending on the quality and design of the clothes. Consumers are willing to spend a lot of money on good-quality apparel because it not only increases consumer satisfaction but also makes them loyal to this particular brand, hence increasing its sales. This garment quality control guide includes the basic and most important areas to consider when it comes to achieving garment quality excellence. When done right, your garments will set them apart from the rest.

Understanding Garment Quality

Quality refers to the quality controllers fabric strength, stretch test colorfastness, smoothness, and general appearance of the garments in relation to what customers expect to get from the fashion house. Customers are always willing to pay for quality products and it is important for the buyer to know that an affordable price does not necessarily mean low-quality garments, as long as they have used good fabric and are very careful in sewing the garments.

The Importance of Fabric Selection

Fabric is the backbone of all great pieces of clothing that one can sport throughout their day or occasions they attend. The choice of raw materials is highly relevant as it defines all the parameters of the the final finished garment product: from the facilitation of wearing clothes to the overall appearance. When choosing fabrics, consider the following:

Fiber Content

The civil dress mostly employs natural fabric such as cotton, wool, and silk due to their comfortable nature and ability to absorb sweat. But, fiber like polyester and nylon can provide durability for the fabric and the fabric may also have quality of being non-wrinkle and non-shrinkable.

Fabric Weight

weight of the fabric is another factor which has some effect on the drape of elastic fabric of the garment and its touch sensation. When it comes to selecting appropriate fabrics for specific garment styles, experience shows that various heavier fabrics will suit well in the construction of structured garments and other lighter and softer fabrics will fit well in the creation of some of the more flowy garment designs.

Fabric Testing

The next tests to be carried out on the fabric include assessment of colour fastness, shrinkage, and tensile strength.

Factors to Consider in Apparel Quality Control

It is imperative that aspiration towards the desired quality level of apparel is achieved by paying attention to different aspects of initial stage of production. There is a list of general factors that can be considered significant for the stage under discussion, each of which is described with a separate paragraph.

1. Fabric Quality

Materials are the foundation of any fantastic piece of clothing; it cannot be overemphasized how important a role they play in the qualitative and production quality of apparels. The fiber used, the weave structure and even the finish that is given to the fabric all have an important role to play in giving the final product its durability, softness, crispness, and sheen. Controlling continuity of the fabric and therefore performing vigorous tests on color fastness, shrinkage, and tensile strength is important. While selecting fabric, one should not ignore its relevance on the quality and endurance of the garments and customer satisfaction level.

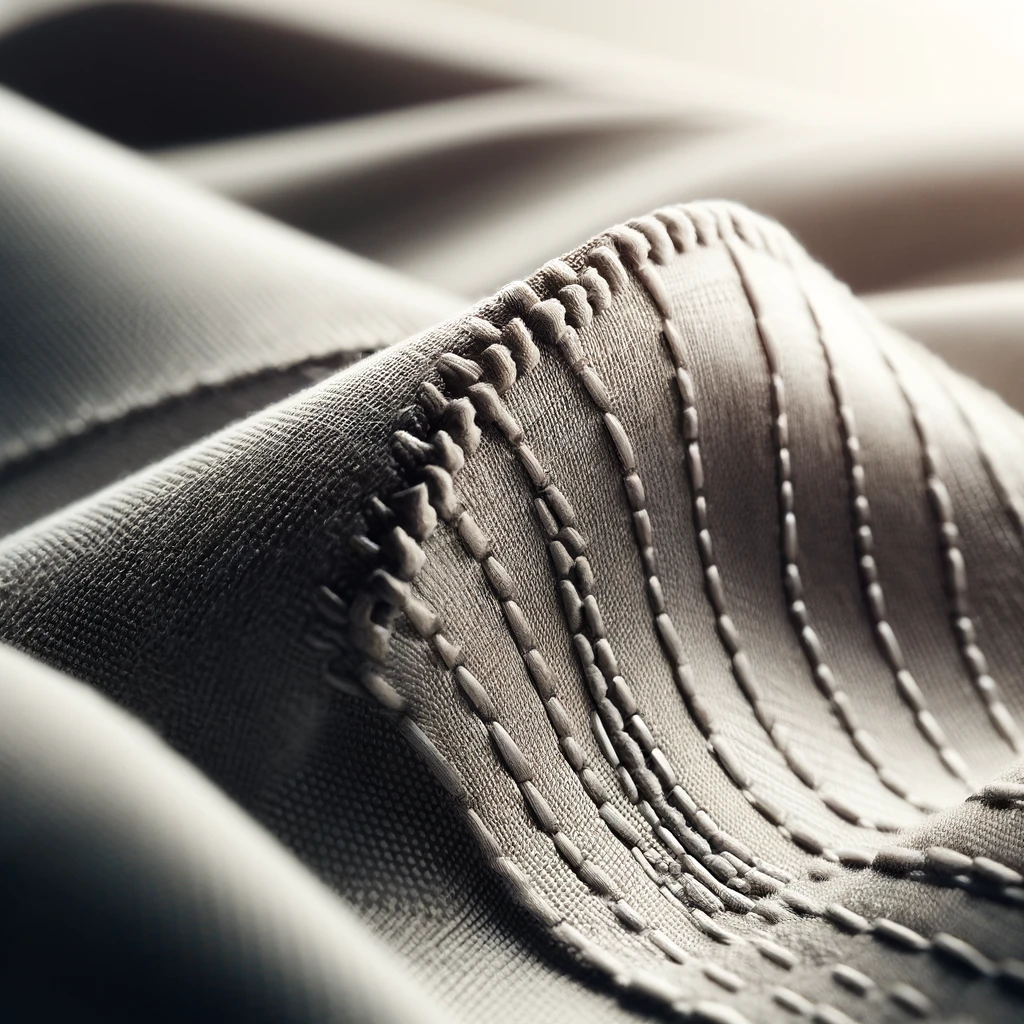

2. Stitching and Seams

It is also important to consider stitching and seam qualifications as far as the quality of the garment and its finish are concerned. Safeguard stitching also helps the fabric from fraying and also holds the structure of the costume after washing. Stitches like double topstitching, over-stitching, and reinforcing add extra strength and toughness to the item, especially in portions that experience high stress. Solution: There is another type of checks carried out periodically during the sewing process which for quality checking also identifies non-conformities.

3. Fit and Sizing

Fit is crucial for the success of any garment, along with making sure that the size is correct for the customer. I also want to highlight the fact that inconsistent sizing will result in high return rates, which means customers will be dissatisfied with products. Getting the right patterns and grading can help in achieving correct fitting of garments, regardless of their size. Annual fittings, also incorporating wear-test data in response to these issues, ensure that consistency and adequate comfort are applied across all sizes.

4. Finishing Details

Removing seams, creating a selector, button or zipper closing, and other forms of trimming create a stunning and quality outlook of the garments. These elements need to be affixed firmly and determinedly to serve their function effectively. This means that to give a sewn garment the best look and durability in terms of fits and closures, issues like clean hems and the proper use of fasteners should be observed. Paying attention to them is a way to produce work that is not only accurate but also well-finished.

5. Quality Control Inspections

It simply highlights that quality control check must be carried out on the entire shipment on a regular basis, irrespective of the stage of the productive cycle. Preventive checks occur when the work is in progress with the aim of eliminating defects right from that stage, while receiving inspections happen at the end of the production line with the aim of ensuring that the product is of acceptable quality. Much specific attention should be paid to the identification of various defects, correct dimensioning of every element and detail, and, finally, the proper application of finishing surfaces. A highly effective quality assurance system reduces the likelihood of bringing in substandard products, which can be a customer-organizational disaster.

6. Inclusion of Ethical and Sustainable Practices

New policies and measures should regulate the use of ethical and sustainable approaches within the production process. Maintaining fair labor practices and equal working conditions not only embraces the right levels of ethical reason but also the public image. According to the topic, the two major factors are the effective use of materials to meet the environmental needs of a growing population of consumers, as well as the matter of being able to minimize the use of materials in production. Some of these practices can be very useful in developing customer goodwill and loyalty Here are some of the techniques of transparency.

7. Continuous Improvement

Upon its processes, it is crucial to have quality control standards that are continually improved. By evaluating the quality control procedures from time to time and incorporating the new ideas and complaints from the customers, new specific areas of concern can be realized. Proper staffing also ensures regular mechanical and visual inspections, capital investment for future production line upgrades as well as training for employees to retain efficiency. This assures the brand of a continuous enhancement in their products’ quality, hence creating a brand that offers high-quality apparels.-

Benefits of Apparel Quality Control

Apparel quality control is a critical and advantageous practice in the textile and garment industry itself, as it offers numerous benefits to those manufacturing process who apply it.

1. Enhanced Customer Satisfaction

High-quality garment and manufacturing capabilities such that they meet or above customer expectations or even have the potential to excel at the expectations of the end users, thereby increasing their level of satisfaction. Customer satisfaction is one of the key indicators of customer loyalty, meaning more sales and thus increasing the brand’s sale due to referrals.

2. Low Experiences sales and fewer complaints

Quality assurance minimizes the chances of producing substandard, low-quality, or non-feasible products. This leads to reduced return rates as well as fewer complaints from customers, and the time and effort that the company may spend trying to handle such incidences is reduced.

3. Improved Brand Reputation

The generally accepted view is that a consistent supply of good products lays the foundation for brand building. Brand image makes customers be attracted towards the products or services offered and they trust the brand that occupies the market.

4. Cost Savings

Quality control is an activity that requires an investment during the initial stages of operations; however, it results in cost savings in the long run since it reduces wastage, the need for reprocessing, and rewards avoided due to non-compliance with the expected quality of clothing manufacturers of products. Consequently, the generation of more revenues leads to reasonable prices and to better profit margins on F&B sales.

5. Compliance and Safety

Fabric quality assurance checks guarantee garments’ conformity to norms set by industry and Safe Working regulation. This means that compliance works to the advantage of the brand by mitigating the risks of legal implications while endorsing the certainty of product quality and safety for consumers.

6. Higher Market Competitiveness

Markets with a large variety of other clothing brands, including apparels that is priced reluctantly high quality clothing manufacturers but of superior quality, can easily find a niche. Thus, quality assurance gives the brand a brand a competitive advantage—the ability to stand out and appeal to the value-conscious customer into your clothing manufacturer international markets.

7. Longevity of Products

More often than not, it is coupled with quality, which denotes that the garments are more resilient and thus can wear longer, making it more affordable for customers. This leads to strengthening brand perception and customer loyalty from a long-term perspective.

8. Job satisfaction and organizational commitment

Quality control creates a sense of ownership and pride among the employees since the work is concise on the company. Employees who have a vision of their productivity enhanced through quality work and delivery achieve higher levels of motivation and productivity.

Why do you need a garment quality control checklist for textile and apparel inspections?

The Role of Garment Quality Control Checklist with regard to Textile and Apparel Inspections

1. Consistency

A quality control checklist helps guarantee that every garment of clothing manufactured does not relax the standard. It can help to identify key problem areas and not expose the company to potential claims from clients by requiring them to produce the same quality of product from one batch to the next.

2. Comprehensive Evaluation

Check list activities are on aspects involved in garments production such as fabric, trims and accessories, washing and finishing. They include the following: This provides a full check on different occasions so that to get rid of all probable problems at different phases.

3. Efficiency

Applying a checklist reduces inspection time due to everyone knowing what to check for. He pointed that the checklist is very helpful to the inspectors, as they can easily go through production inspection using it to ensure that they do not leave out any key quality indicators for examination, thus saving a lot of time costs effort and energy during every inspection.

4. Error Reduction

Templates used lessen the possibility of human error due to factors such as exhaustion, forgetfulness and confusion by giving the inspector a guide to follow. This helps eliminate cases of missing out on some quality factors during the inspection process and increases the chances of a correct and complete check.

5. Documentation

An audit checklist has historical evidence of the actual inspection carried out in a specific product. This documentation is useful to compare quality between different periods of time, review troubles that do occur routinely, and prove efforts in matters of quality to those who fund or support the quality control process.

6. Continuous Improvement

Hence, the checklist for inspection mechanical examination and testing can be reviewed and reformatted with new and improved items depending on the findings of the inspection fatigue test and feedback from the customers on perceived quality of the products that have been produced. This can culminate in added improvements to garment quality and customers’ perceptions towards the products.

7. Compliance

Checklists help the inspector to remain focused and make sure that he or she does not exceed any regulatory or industry standard requirements. This assists in ensuring that safety and quality standards are followed so that the brand is not entrapped in a legal scandal while improving its image.

Apparel Quality Control Standards and Regulations

Key Principles in Apparel Quality Control Standards and Policies

1. ISO 9001

According to the prior work and definitions, Quality Management Systems (QMS) can be defined as composite of various control forms and procedures that an organization has in place to ensure that products or services required by clients or customers meet these expectations.

This specifies the requirements for a Quality assurance and System. It is also used to standardize quality assurance by developing procedures for tasks such as quality assurance, management’s commitment, resources directives, and products development.

2. ASTM International Standards

ASTM is the Society that offers specification guidelines physical tests and test methods of pertinent attributes of textiles and apparel, for example, tensile strength, wearing strength, and color fastness. These standards help establish that the products have certain performances in relation to factors expected.

3. AATCC Standards

AATCC is an organization that deals with the formulation of standard practices, test methods, and technical information connected with textiles and apparel, with specific reference to colorfastness, chemical properties and the behaviour of fabrics. Conforming to these standards makes it easier to retain high standards of products that the society deserves.

4. CPSIA: The Consumer Product Safety Improvement Act

The CPSIA is the law that elaborates safe standards concerning children’s clothes in the United States. It has provisions on the presence of lead, phthalates and flammability for children’s clothing, and, first and foremost, shouldn’t harm children.

5. REACH Regulation

REACH is the EU regulation that outlines the initiative for the registration, evaluation and control of chemical substances in use and production. It also helps to make certain that garments are not manufactured using chemicals that are dangerous for use, thus conserving human and environmental health.

6. OEKO-TEX Standard 100

OEKO-TEX Standard 100 can be a label that identifies the quantity of potential injurious chemicals in textile products. An accredited product is one that goes through a process where it is tested and proven to be safe from the listed dangerous chemicals.

7. GOTS: Global Organic Textile Standard of GOTS

Gotts defines standards for the environmentally sound processing of garments and other articles woven from organic, natural fabrics. From the processing and manufacturing right up to the packaging, labeling, and even distribution, they ensure that it happens tastefully with regard to the environment and society.

8. CPSC Flammability Standards

It is worth noting that the Consumer Product Safety Commission or CPSC, does have flammability requirements specifically catered to textiles and apparel, including children’s sleepwear. From these standards, it becomes clear that garments must be safe so that they do not pose or contribute to fire-related accidents.

9. WRAP: Global Product Advertising: Responsible Production Accreditation

WRAP is a certification program that is based on the lawful observation of humane and ethical manufacturing. It prescribes how and where apparel is made, including the rights of workers, their health, and the facility’s ecological footprint.

10. ANSI Standards

The American National Standards Institute, or ANSI, gives standards on various garment production in terms of safety, labeling and performance. These standards help guarantee that most clothing items will conform to the required national quality and safety standards.

Precision in Pattern Making and Cutting

Especially when it comes to garments, drapes, and detailing, it is extremely important to get the right pattern and fabric cut. Make sure that when patterns are being made, they are very well done without any kind of flaws and it is also important to ensure that the cutting process is done without causing any flaws in the fabric spreading the materials. Key points to focus on include:

- Pattern Accuracy: To avoid the complexity of having to produce multiple sizes of dresses, use CAD technology in designing the patterns.

- Grain Alignment: When cutting the fabric, make sure that the fabric grain is lined up properly so that, during the wearing process, it does not ‘cling’ or’stretch’.

- Cutting Tools: Always and without any exception, ensure that all of the cutting tools being used are sharp and that they have been maintained appropriately so that clean edges can be achieved.

Excellence in Sewing and Construction

Here, construction refers to statistical process control how the garment has been made in terms of sewing to arrive at the final piece of clothing. Hand sewing involves more precise work as compared to other methods of sewing and this is true since high-quality sewing ensures that, upon completion of the work, the best results are achieved. Key elements to consider:

- Stitch Quality: Choose stitch lengths and types that are suitable for fabrics that are used in specific items of clothing. Make sure that the height of the stitches is uniform and that the distance between them is also consistent.

- Seam Finishing: Use finishing techniques such as overlocking, binding, or French seams in order to avoid fraying and increase the wear ability of the stitch.

- Fit and Structure: Add the right accessories, such as labels, sewing the inside of the garment, belt lines, stiffeners, and other parts that will help to give the garment its right shape and fit.

Quality Control and Inspection

High quality standards have to be followed and can only be achieved if appropriate quality control measures are put in place from one level to the next. This includes:

- In-Process Inspections: Cars should be inspected frequently during production to identify problems as they arise so that appropriate actions can be taken before they develop into more significant problems.

- Final Inspection: Take time and review the quality of all the garments that came out of the wash, especially as regards defects or lack of uniformity in quality.

- Customer Feedback: Always look at the feedback given by the customers with the aim of finding out the repetitive complaints that relate to quality.

Why is the use of high-quality garments important?

The importance of high-quality garments is imperative, and this can influence the customer satisfaction that a particular brand garners and, therefore, the economic sustainability of a business. Apparel that is better constructed and of better material is more comfortable to wear, will last longer, and will look better the longer it is used; this will give the customer reasons to come again and buy the products. These garments also have a longer durability, which offers customers an added lifespan of the garments they buy, besides coming at a cheaper price, making them more economical and requiring fewer replacements, which dangers the ecological system. On the same note, ensuring that quality garments are crafted contributes to the creation of a strong and positive perception about the brand since customers avoid instances where they are subjected to inferior brands. Furthermore, focusing on garment quality is crucial for gaining customers’ confidence and preventing high rates of returns, which can signify a more profitable business model in the long run.

What Are the Effects of Bad Quality Management on Apparel?

The consequences of poor or ineffective management of quality in the apparel industry are rather destructive to a business. This is because poor quality management results in high customer returns, high defects, low customer satisfaction, and low sales. This leads to cases where customers give their backs to negative criticism, brands suffer losses, and their standings suffer from a loss of customer trust. Moreover, it creates extra expenses in terms of production, as it requires rework, materials, and lower efficiency. Other key risk factors may also emerge if the products or services fail to meet some general safety or regulatory requirements. Poor management skews the company’s revenues negatively, impairs its ability to compete favorably in the market, and consequently causes long-term business failure.

What Are the Benefits of Good Garment Quality Standards in the Textile Industry?

It is evident that the textile industry has much to gain through the proper implementation of quality standards for garments. Adherence to quality is useful because it enforces high quality standards, among other benefits such as customer satisfaction and consequently increased loyalty. They minimize the risk of parasites and losses, including the cost implications of reworking or disposing of faulty stocks. Effective standards also help in the creation of a good brand image and market competition, which gives companies the opportunity to charge premiums for products. Playing by the rules ensures low legal liability and high levels quality that meet customer expectations and of safety for consumers. Other benefits include effective quality control since the use of QMS will reduce the cost of fabric quality control and enhance efficiency and profitability throughout the organization. All in all, it is less risky to follow high standards of garment quality all the time, contributing to business continuity and prosperity.

Conclusion

This work is dedicated to exploring the main aspects that are to be considered to achieve and maintain the high quality of garments: proper choice of fabrics, alterations in fabric cutting, and sewing techniques, and strict quality control. By addressing these areas, you can cultivate the production of apparel that meets or surpasses the clothing industry’ standards of quality and the quality requirements of customers. Giving customers value for their money will make your brand stand out among the numerous fashion enterprises, which will directly translate to higher sales and revenues in the long term.

You stand to benefit from positive changes once you set yourself up to identify the causes of garment quality issues and cultivate the necessary habits with the supply chain.