There has always been a rapid growth in t-shirt printing techniques, especially in the methods that are used to print personalized pictures on the t-shirts. Regardless of the type of industry or your activity scope, or if you just want to create customized products for your friends, acquaintances, or family, it is crucial to learn about the most popular methods of t-shirt printing. Without further ado, let us discuss the top t-shirt printing techniques, their advantages, and how to identify which method will best suit your t-shirt into the best t shirt printing.

The Most Popular T-Shirt Printing Types and their Pros and Cons

T-shirt colour printing is a technique that has evolved over time to become one of the best ways to put on a personal touch, promote businesses, and come up with unique gifts. So having examined the various types of printing below, there are still drawbacks to each so that the most appropriate one can be chosen. Here’s a detailed look at the most popular t-shirt printing types and their respective advantages and disadvantages:

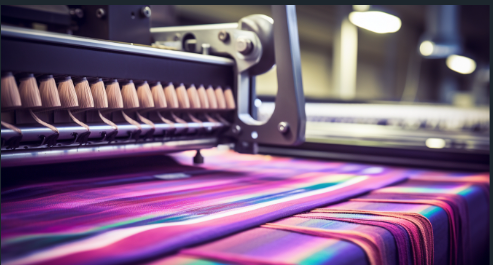

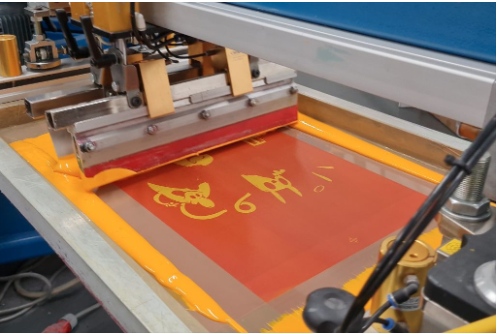

1. Screen printing

Overview: Silkscreen printing t-shirts is also known as screen printing, which is one of the earliest forms of t-shirt painting methods. It incorporates the preparatory process of stenciling or screening, followed by a process of layering ink on the t-shirt.

Benefits:

- Durable and long-lasting prints.

- Cost-effective for large batches.

- Bright colors with significant contrast and minute differences between areas of color.

Best for: small orders, low complexity of the design with few hues and pigments, areas of solid colors.

Limitations:

- This is a disadvantage because it means it is not cost-effective to carry out small runs, especially in arts or graphic designs.

- It is also quite cumbersome and costly when one has to deal with intricate designs that have many colors incorporated.

2. Direct-to-garment printing

Overview: Domino digital thermal transfer (DTG) printing calls for a digital inkjet printer that deposits water-soluble inks on fabrics. This technique can be utilized as a way of achieving high print resolution where full-color images can be reproduced.

Benefits:

- Perfect for mini-run orders or creating a masterpiece for one event.

- It has the ability to generate intricate patterns of various colours, differing from the colour-changing dials of aquarium fish.

- Slightly tight, soft feeling as the writing is made and the ink is soaked up by the material.

Best For: These are services for selecting custom designs, fine artwork, and products that involve low runs of production.

Limitations:

- The pricing usually reflects a higher price per piece or component when a large order of the particular product is placed.

- If possible, use 100% cotton fabrics for the best result.

3. Heat Transfer Printing

Overview: Heat transfer printing requires one to print the design on heat transfer paper and then apply heat and pressure to the t-shirt in order to transfer the design into your heat press printing.

Benefits:

- Experimental: these machines can print elaborate designs with different shades in one run.

- It is applicable to many small and large-scale orders and could be field-used repeatedly.

- It can be applied for different types of fabrics due to its versatility of working under various conditions.

Best for: Each is unique in some way and excels in the areas of full color available for each print and on-demand printing.

Limitations:

- Prints may also peel or discolor with time, making the paper contain poor-quality prints.

- It is not as long-lasting as screen printing ink or DTG.

4. Dye Sublimation printing

Overview: Sublimation printing involves the use of heat to transfer the dye on the fabric out onto synthetic fabrics. It evaporates when heated and sticks to the patient’s skin like a gas, particularly attaching to the fiber in a piece of fabric.

Benefits:

- Produces vibrant, long-lasting colors.

- It does not peel, comes with no cracks, and is not prone to fading.

- Suitable for all-over prints.

Best For: Unit: technical aspects Polyester fabrics, with newness returning more often and ranges associated with sportswear and all-over printed designs.

Limitations:

- This only works on light-colored synthetic materials You can rub the solution between your hands first and then apply the dampened paste on the stained area.

- It works only for limited fabric types (mostly polyester), although homepage promises latest fabrics and features.

5. Vinyl Cutting

Overview: This is the process of designing a picture using plastic cutters, which is done on sheets that have different colors of vinyl, then they are ironed on to the t-shirt.

Benefits:

- Convenient for linear designs, logos, and texts, and highly suitable for such work.

- Durable and long-lasting.

- Ideal for entrepreneurs who require limited volumes of products, such as branding materials for special occasions.

Best for: apparel products, garments, polos, sports wear, team wear, t-shirts, jerseys, team uniforms, and customized unique designs.

Limitations:

- Even though it provides good resolution and supports layering, it is not ideal for intricate, multiple-color patterns.

- Can feel dense or rigid on the material that it is applied to or made on.

6. Discharge Printing method

Overview: Using water-based ink discharge printing on the fabric, where water would wash away a dye and in place color remains, which is usually white or off white in color.

Benefits:

Soft, breathable prints.

Vintage, distressed look.

Suitable for dark-colored fabrics.

Best for: Graphics and themes that can be traced to a bygone era with the use of delicate colors on heavy blacks.

Limitations:

One of the flaws of this design is the availability of few colors: mostly light colors on the dark cloths.

It may not work out well on synthetic fabrics.

7. Embroidery

Overview: Embroidery t-shirt printing requires sewing the design on the t-shirts using threads on the material chosen. This method produces a more resilient, rough, and official finish, which is perfect for any decoration. Many approaches are possible, and each has its strengths and weaknesses, as well as the best and most appropriate uses.

- Standard Embroidery: A small spindle is used to bring about designs through a single thread. It is best used to create logos and text images. Durable and versatile.

- Appliqué Embroidery: Applique fabric pieces to t-shirts, with stitching around the edges of the fabric piece. It’s ideal for intricate and large designs with depth or texture such as complex company logos, lettering and embossing.

- 3D Puff Embroidery: Apply foam under stitching so the whole thing looks raised. Best for making logos and large letters that are to stand out from other items on a balancing T-shirt design.

- Chenille embroidery forms a soft silky or velvety surface with loops of yarn on the surface of the fabric and interconnecting loops of yarn with each yarn passed underneath the first. Good for making large letters and simple-shaped words or drawings.

- Embroidery with Sequins and Beads: Feb appeals for sparkle and texture and might include sequins or beads where appropriate. Ideal for fashion apparels, accessories and prints on t-shirts and other novelty wears.Choosing the Right Method

- Standard: If you desire simple designs that are professionally done then this software might be perfect for you.

- Appliqué: When it comes to large and pasty work, they are perfect to be used because they do not produce smears when applying color to large areas or sections with heavy texture.

- 3D Puff: For getting effects which are going to be quite bold and raised a little from the material’s surface.

- Chenille: Picture print with thick, raised surfaces: For plush, textured designs.

- Sequins and Beads: To add aesthetic appeal and for stylish designs.

9.

Overview: Bleach printing entails applying bleach on the surface of the t-shirt in a way that will give it a lightened up look to achieve a particular design.

Advantages:

Unique Designs: This is true since each shirt has its unique pattern because of the spills of bleach which are difficult to control.

Cost-Effective: As for the components, it can be seen that they are very inexpensive and little equipment is needed for the production type.

DIY-Friendly: Easily practiced at home using standard hand tools.

Best For:

T-shirts referring to black color, production of designs which have distressed and vintage appeal.

Limitations:

Fabric Compatibility: Recommended for use of 100% cotton fabric, do not use synthetic fabric as may not take the bleach well.

Durability: Exposure to this harsh chemical for a long time can lead to over-bleaching which causes the fabric to become weaker.

Health Concerns: The handling of bleach requires caution with adequate ventilation and safety gears to avoid the health risks associated with the chemical.

10. Foil Printing method

Overview: This process marries the surface of t-shirt to a special adhesive then applies a metallic foil on the adhesive using heat. Finance the production of a new shiny reflective material that has the appearance of metal.

Advantages:

Eye-Catching: Creates bright and shiny, having a sheen that makes stand out from the rest.

Versatile: It can be used in conjunction with other forms of printing for the art works intended for printing.

Durable: Long-lasting if it has been applied properly in the first place and if proper care is given to the fence.

Best For:

Fashionable and trendy designs.

Making accents of some elements in a design.

Promotion material and events.

Choosing the Right T-Shirt Printing Technique

When selecting a t-shirt printing technique, consider the following factors:

Quantity

On a macro level of production and design, screen printing is better used than DTG and heat transfer for small quantity production.

Design Complexity

DTG and sublimation are great for showcasing detailed, intricate, and multi-colored images while vinyl cutting and screen printing can be more suitable for less detailed designs.

Fabric Type

For polyester materials, sublimation printing is the best method to use, while discharge printing is also great for dark-colored cotton garments, and lastly, the DTG technique is ideal for producing well-defined and detailed printings on the cotton fabric.

Budget

When it comes to the number of pieces to be printed, for large orders, it will be more efficient to use screen printing whereas heat transfer and DTG might be cheaper works for little orders.

Which T-Shirt Printing Methods Should You Choose (Comparison)?

T-Shirt Printing Methods Comparison

Screen Printing:

Pros: It is known for its wear resistance, is economical in wholesale rates, and gives bright shades. It is suitable for large orders and the production of cheap clothing because it uses relatively simple designs.

Cons: It takes a lot of time to set up and is not suitable for designs with fine, intricate detail or those utilizing many colours.

Direct-to-Garment (DTG) Printing:

Pros: Ideal for intricate saturated patterns with no minimal bulk order, and offers a delicate touch.

Cons: More expensive on a per-unit or per-piece basis on large volume orders and ideal for 100 percent cotton material.

Heat Transfer Printing:

Pros: flexible and capable of serving both individual and bulk orders; compatible with all fabrics.

Cons: Paper prints may come off in great, thick flakes, while others may peel or crack after some time, making the making the transfer seem thick and plastic-like.

Sublimation Printing:

Pros: Creates highly vibrant, long-lasting colours on skin and is perfect for large lettering Intent: Very soft to the touch.

Cons: This is suitable for lightly coloured synthetics only and involves the use of special equipment.

Vinyl Cutting:

Pros: Long-lasting, great for small-lettered, large-numbered, or logo imprints, with plenty of vinyl hue options.

Cons: It is not very suitable to plan intricate ones because the process can feel bulky or rigid.

Discharge Printing:

Pros: To be specific, it gives out very fine prints with an old-world charm feeling and can last for a very long time.

Cons: It is only applied in designs that require a lighter color on the darker clothes and involves the use of chemicals.

Foil Printing:

Pros: A metallic effect is created, it has high visibility and it can be used with other processes for more elaborate patterns.

Cons: It has to be washed with a lot of precaution and is generally not good for designs that are highly detailed.

Embroidery:

Pros: Very tough in appearance, versatile for all fabrics and textiles and blends well to give an increased texture to the fabric.

Cons: Some of the disadvantages of using this technology include: higher cost, especially in the initial stages of adopting this technology; designs that are complex will cost more; and there are also setup fees when it comes to digitizing designs.

Frequently Ask Questions (FAQs)

Frequently Asked Questions (FAQs) about T-Shirt Printing Methods

The most often used t-shirt printing styles embrace screen printing, direct-to-garment (DTG) printing, heat transfer printing, sublimation printing, vinyl cutting, discharge printing, foil printing, and embroidery.

Screen printing is efficient for making bulk items and results in long-lasting and bright colors.

Direct-to-Garment (DTG) Printing: Semi-automatic embossing is perfect for intricate designs, multiple colored images, and small quantity printing because of its finesse.

Embroidery: A classic characteristic of the fabric is that the embroidery designs are properly cared for and will not easily wash off with repeated washing.

Sublimation printing is most recommended for cool or pale-colored fabrics and synthetic fibers such as polyester, as it gives a bright and durable color result.

Foil Printing: This method produces thin layer metallic design and is appropriate when the clothing is to have fashionable and trendy designs.

Vinyl Cutting: Great for personalization of names, numerals and logos given that it has high degree of resistance, it comes in various colors.

Discharge Printing: Gives soft and breathe easy prints with a wash away effect or weathered look of bygone era, optimal for black colored cloth.

For example, they can think of order size, product detail, the type of material to be used, and the amount of money to be spent. For bulk production, screen printing takes the cake especially when the design is simple, whereas DTG and sublimation are perfect for designs that have fine details, colorations, and selectively small scale production. There is no doubt that names and numbers are better suited to vinyl cutting while embroidery is ideal for projects which require high levels of abrasion and professional touch.

Conclusion

Selecting the appropriate technique of t- shirt printing from a host of available methods is critical to the success of the intended campaign. Although every stereoscopy technique has some advantages and some extents of drawbacks, each of them is appropriate for some application. For big quantity, simple designs, and more stiffness in the tee shirt screen printing would be the best choice. So far, the advantages of direct-to-garment (DTG) printing are compelling especially for short production jobs that require intricate designs involving the use of numerous shades of color. Heat transfer printing is ideally suited to different types of fabrics and as for the small- and large-scale order it is also quite simple and efficient to your t shirt business. All-over printing has better results when done by sublimation printing since it is ideal for polyester materials and results in bright and durable prints.

Vinyl cutting or vinyl printing is particularly appropriate when it comes to writing names, numbers and logos, because it is quite wearable and then is available in abundance of colors. What makes Discharge printing more interesting is that it produces a vintage, distressed texture that is best for dark clothing. This is making foil printing to produce metallic prints that are appropriate for product branding on material hoods, shirts and different accessories. Embroidery is professional and is more long-lasting as compared to other printing techniques and hence it is best suited for business employee wear and other gift items.

In this way, it will be possible to realize the benefits and drawbacks of every method, and select the best option based on the design complexity, the number of ordered products, the specific fabric, and strictly defined budget. This timely guide provides you with the essential information on how to get started and navigate through the process of t-shirt printing to ensure that the final product fits your personal requirements.